Top New Enhancements in SOLIDWORKS R2024x FD03: Boost Your Design Workflow

Introduction

SOLIDWORKS is a comprehensive computer-aided design (CAD) and computer-aided engineering (CAE) software suite developed by Dassault Systèmes. It is widely used in various industries for creating 3D models and 2D drawings of physical components, as well as for conducting simulations and analyses. The software supports the entire design process, from concept development to detailed design, simulation, and manufacturing.

The latest update of SOLIDWORKS, specifically the Design and Modeling R2024x FD03, introduces a range of enhancements aimed at improving user experience, efficiency, and design capabilities. This update is particularly significant for professionals in engineering and product design, as it addresses common challenges faced during the design process.

The latest R2024x functional delivery (FD) 03 update brings exciting advancements to key tools in the SOLIDWORKS family, including 3D Creator, 3D Sculptor, Manufacturing Definition Creator, and 3D SheetMetal Creator. This update is more than just a technical enhancement; it’s a step toward making your design and manufacturing processes more intuitive and efficient. Whether you’re shaping innovative designs with 3D Sculptor or streamlining your production workflow with Manufacturing Definition Creator, this update offers new features that simplify complex tasks and enhance precision. It’s all about empowering you to bring your ideas to life with greater ease and accuracy. Below, we will explore the key features and improvements that come with this release.

What’s New in SOLIDWORKS R2024x FD03?

The latest SOLIDWORKS R2024x FD03 update is packed with exciting new features! You can now perform interference checks on surfaces, making it easier to spot and resolve potential issues. Collaboration has also been improved, allowing electrical and mechanical designers to work more seamlessly together. Plus, you can now access SOLIDWORKS PDM directly within 3DEXPERIENCE SOLIDWORKS.

These enhancements are available across 3DEXPERIENCE SOLIDWORKS, SOLIDWORKS with Cloud Services, and SOLIDWORKS with Collaborative Designer for SOLIDWORKS.

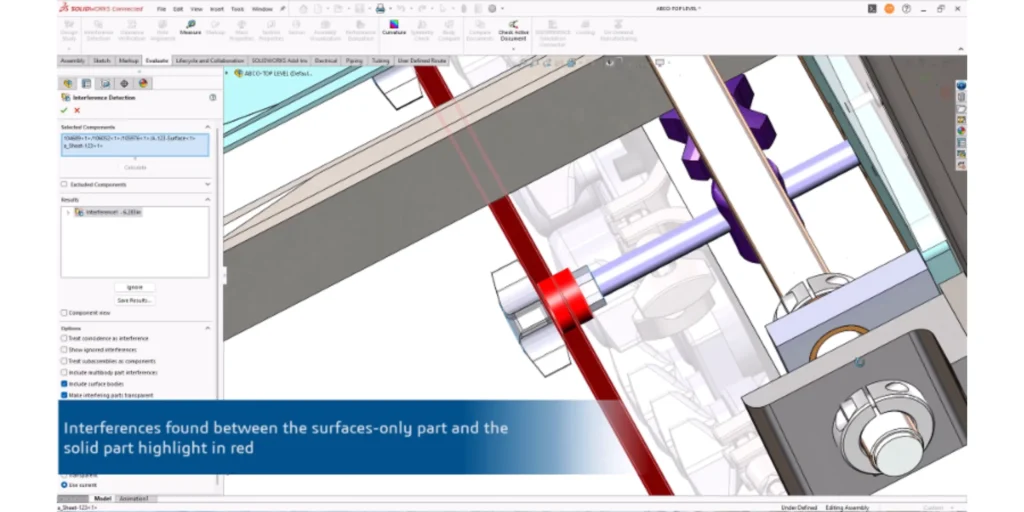

Check Interferences Between Surfaces and Solid Parts

Imagine you’ve been working on a complex assembly and need to ensure everything fits together perfectly. Previously, interference checks in SOLIDWORKS allowed you to identify clashes between solid parts, which was incredibly useful. But what if some of your components are surface bodies, such as imported geometry?

Now, with the latest update, SOLIDWORKS has expanded its capabilities. You can not only check for interferences between solid parts but also between solid parts and surfaces. Plus, it doesn’t stop there—you can now run interference checks between surfaces themselves. This enhancement is a game-changer, especially when dealing with imported geometry that might come in as surface bodies. It helps you catch potential issues early, ensuring a smoother and more efficient design process.

ECAD/MCAD Improvements

Communication between electrical and mechanical designers can often be inefficient and cumbersome. With CircuitWorks, these barriers are removed, streamlining collaboration. Mechanical and electrical designers can seamlessly share updates and modifications, capturing circuit board changes more effectively. This improved workflow allows electrical designers to quickly understand and compare the latest board assembly with previous versions, enhancing overall ECAD/MCAD collaboration.

With the new Cadence OrCAD X integration, you can easily identify and export PCB assemblies to CircuitWorks for review by your electrical designer.

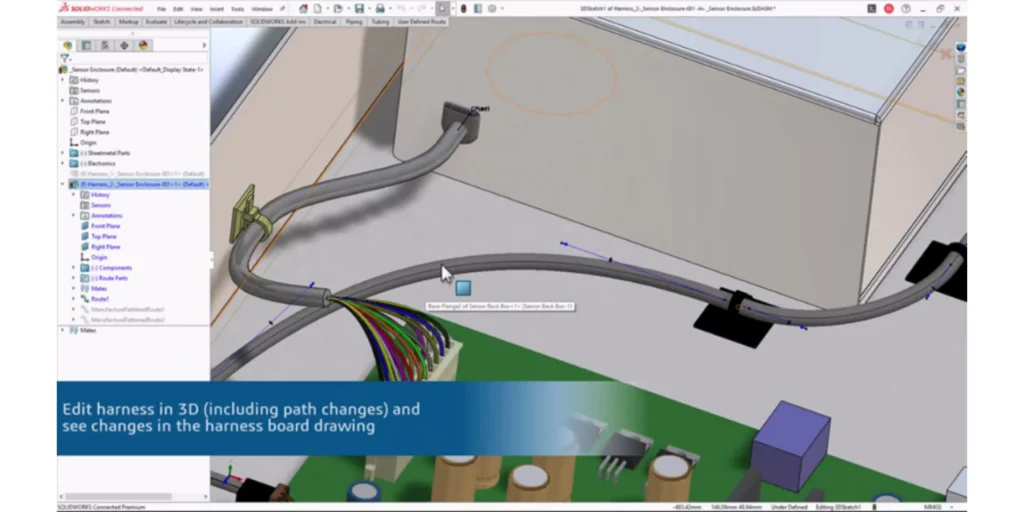

Designing and manufacturing harnesses and wires can be intricate. To streamline this, you need to flatten harness and cable information for production. While you’ve always had flattening options, now you can edit harnesses with more flexibility. For example, you can use the straighten edit method to adjust bundles or individual wires in flattened assemblies, employing features like ‘reverse direction’ or ‘% change’ to refine your designs.

With the latest updates, making changes to your electrical harness design has become much more streamlined. When you adjust your design, incremental updates to the flattened configuration will be predictable, and you can keep any manual tweaks you made to the original design.

Handling splices is easier too. You can now manage splices located in bundles or loops more efficiently, position junction points precisely on the flattened plane, and even rotate multi-conductor splices during the flattening process.

These ECAD/MCAD enhancements give you greater control over wire flattening, speed up the implementation of design changes, and improve the overall efficiency of harness design and documentation. You’ll find better handling of electrical splices and a smoother workflow in your flattening tasks.

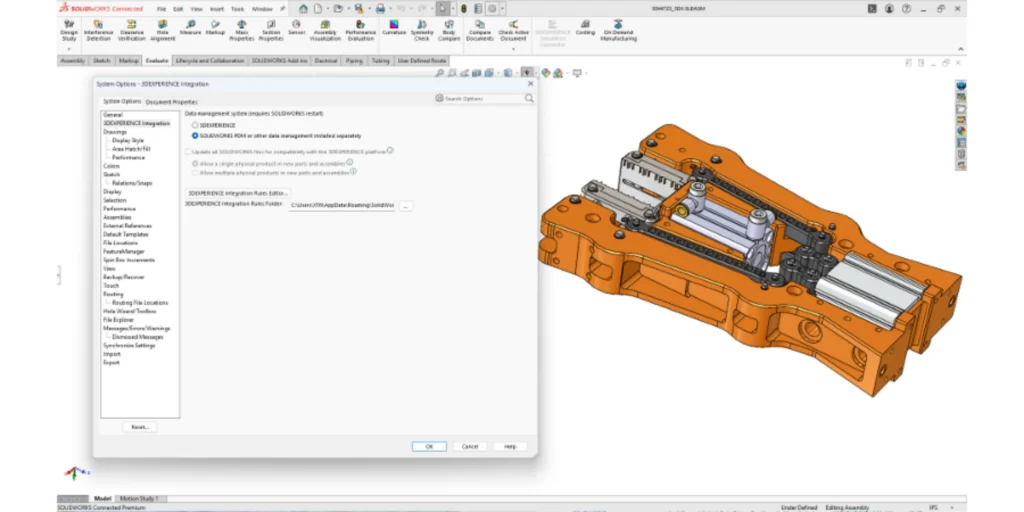

Integrating SOLIDWORKS PDM with 3DEXPERIENCE SOLIDWORKS

We’ve got some great news for those using SOLIDWORKS PDM: 3DEXPERIENCE SOLIDWORKS now offers a fantastic new feature! You can save your parts directly to SOLIDWORKS PDM right from your local machine. This new option streamlines your workflow and keeps everything organized with ease. Happy designing!

Note: We’ve gathered this information from the official SOLIDWORKS website. For the latest updates and news, please visit the SOLIDWORKS website directly.

About ProtoTech Solutions

At ProtoTech Solutions, we’re passionate about revolutionizing the way industries approach design and construction. Since our founding in 2005, we’ve been at the forefront of CAD and BIM solutions in India, delivering innovative software tailored for the Architecture, Engineering & Construction (AEC), and Manufacturing sectors.

Our expertise extends across a range of exciting areas, from 3D app development and visualization to cutting-edge AR/VR solutions. We take pride in our CAD design automation and plugin development, helping streamline your workflows. Whether it’s CAD design and drafting, 2D/3D modeling/rendering, or anything in between, we’re dedicated to pushing the boundaries of what’s possible and making your projects a success with a focus on harnessing the latest technologies.

We work closely with our clients to understand their needs and deliver solutions that exceed expectations. Our goal is to be a trusted partner in your success, providing the tools and support necessary to achieve your objectives. Learn more about