The Role of 3D Product Configurators in Automotive Industry 4.0

The automotive sector is at the forefront of the fourth industrial revolution, often called “Industry 4.0.” This new era combines digital transformation in manufacturing with intelligent automation, connectivity, and data-driven innovation, resulting in smarter, faster, and more adaptable vehicle production. Industry 4.0, characterized by IoT, AI, robotics, digital twins, and real-time analytics, is redefining how vehicles are designed, built, and customized. In this high-tech landscape, the 3D product configurator has emerged as a pivotal tool, empowering not only OEMs and suppliers but also customers through interactive product customization and seamless B2B product configuration.

This blog explores how 3D product configurators empower automotive companies to embrace Industry 4.0, making manufacturing processes more sustainable, resilient, and customer-centric. We’ll discuss their role in digital transformation in manufacturing, practical examples from OEMs and suppliers, and the measurable impact on the automotive industry’s evolution. Discover why these platforms are now essential for efficient collaboration, enhanced user experience, and smarter supply chains in the age of Industry 4.0.

Automotive Industry 4.0: Market Growth & Scope 2034

Industry 4.0 refers to the ongoing transformation of traditional industrial and manufacturing practices through the integration of advanced digital technologies. In automotive manufacturing, it means leveraging the Internet of Things (IoT), Artificial Intelligence (AI), robotics, digital twins, and complete automation across the entire value chain.

The global Industry 4.0 market reached $160.74 billion in 2024 and is estimated at $190.87 billion in 2025, expected to soar to $884.84 billion by 2034 at an 18.6% CAGR. Within this market, the automotive sector stands out as one of the largest adopters of Industry 4.0 technologies, with a projected CAGR of over 17% specifically for automotive. North America, Europe, and the Asia-Pacific are key regions driving this growth, enabled by connectivity infrastructure and continuous innovation.

Key technologies transforming automotive manufacturing include:

- IoT: Real-time connectivity between machines, sensors, and systems drives predictive maintenance and process optimization.

- AI & Automation: Robotics and AI make production lines smarter, more adaptive, and capable of self-correction—all with minimal human intervention.

- Digital twins: Virtual replicas of entire factories enable simulation, design validation, and optimization before making physical changes.

- Smart Factory Visualization: 3D modeling, data analytics, and digital dashboards provide intuitive control over complex operations.

These advancements support agile production, just-in-time logistics, and mass customization, trends that define the new industrial landscape. Simultaneously, automotive giants like General Motors are weaving AI and machine learning into production, predictive maintenance, and customization at scale, further accelerating the industry’s digital transformation.

The Evolution of Digital Transformation in Automotive Manufacturing

The shift towards digital transformation in manufacturing is reshaping the automotive supply chain. Traditionally, automotive supply chains were compartmentalized, heavily reliant on manual workflows, and slow to adapt to market changes. Today, digital platforms are streamlining supply chain visibility and fostering deeper collaboration among OEMs, Tier 1 suppliers, and end-users.

Critical drivers of this transformation include:

- Efficiency: Automation and integrated software eliminate repetitive processes and reduce human error, improving throughput and responsiveness.

- Sustainability: Data-driven tools optimize resource utilization, reduce waste, and support environmentally sustainable design and manufacturing.

- Customer-Centricity: The automotive industry is moving from mass production to mass customization. Smart platforms enable real-time feedback, supporting the shift towards build-to-order business models.

Smart factory visualization, powered by 3D design and simulation technology, helps manufacturers track, analyze, and improve every aspect of the production process. This fusion between IT and OT (operational technology) allows for greater scalability, adaptability, and value delivery to increasingly demanding automotive markets.

What is a 3D Product Configurator?

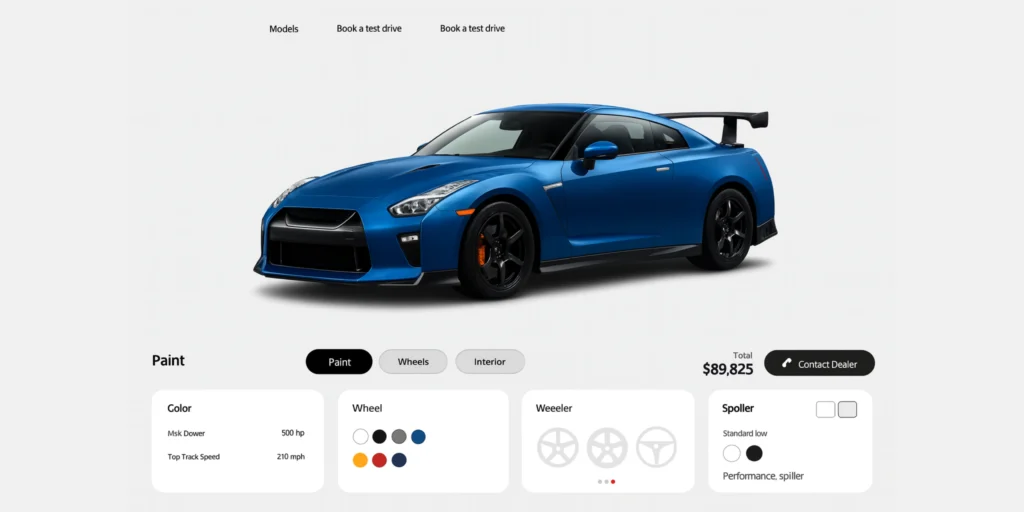

A 3D product configurator is a digital platform that allows users to visualize, interact with, and customize products in real time. In the context of Industry 4.0, these tools are essential for translating complex aerospace and automotive offerings into tailored solutions for each customer or business partner. Core features typically include:

- Interactive Product Customization: Users select features, finishes, and functions, instantly seeing changes reflected in a 3D model.

- Real-Time Rendering: Advanced graphics and physics engines create lifelike visual feedback and validate compatibility of selected options.

- Automation & Integration: Back-end connections with ERP, PLM, and quoting tools (CPQ) automate BOM generation, pricing, and order processing.

In automotive B2B applications, these configurators are vital for:

- Dealerships are configuring OEM vehicles for fleet sales or custom orders.

- Suppliers validating engineering options and precise component specifications before production.

- OEMs are offering fully digital showrooms for end customers to personalize their purchase from the factory lineup.

Such platforms minimize order errors, reduce engineering bottlenecks, and accelerate the Configure-to-Order (CTO) and Engineer-to-Order (ETO) process.

The Role of 3D Product Configurators in Automotive Industry 4.0

3D product configurators are central to the 3D product configurator Industry 4.0 ecosystem. They not only supercharge customer engagement but also integrate seamlessly with digital factory systems:

Integration with Smart Factories and Digital Twins

By linking configurators directly to digital twins of vehicles or assembly lines, manufacturers simulate custom builds, streamline prototyping, and optimize manufacturing flows. Data from user customizations informs downstream processes, minimizing errors and accelerating the entire delivery timeline.

Enhancing Supply Chain Collaboration

Configurators connect OEMs, suppliers, and dealerships, enabling:

- B2B Product Configuration: Direct, accurate exchange of requirements reduces rework and enhances trust.

- Supply Chain Agility: Real-time order data helps forecast demand and orchestrate just-in-time manufacturing.

Boosting Customer Engagement

On the customer-facing side, automotive configurators:

- Enable end-users to tailor vehicles, instantly visualizing different trims, colors, and options.

- Offer real-time feedback, making complex buying decisions interactive and informed.

- Empower sales teams to generate instant, accurate quotes with integrated CPQ tools.

As the market shifts toward SDVs and AI-enhanced manufacturing, configurators become even more powerful, bridging consumer intent with automated, intelligent production.

Impact on Automotive Market Growth & Size

The adoption of 3D product configurators in Industry 4.0 directly correlates with rising efficiency, agility, and profitability in the automotive sector:

- The global automotive market is forecast to grow from $4.54 trillion in 2025 to $7.46 trillion by 2034, fueled by a 5.66% CAGR.

- The product configurator software market itself is set to grow from $1.75 billion in 2024 to $4.40 billion by 2032, emphasizing its rising importance.

Key impacts include:

- Reduced Costs: Configurators cut engineering cycles, reduce rework, and speed approvals.

- Speed-to-Market: Automated order processing and instant feedback accelerate prototyping and delivery.

- Mass Customization: Manufacturers achieve scale without sacrificing flexibility, supporting highly individualized orders at lower cost.

As digital transformation in manufacturing deepens, 3D configurators act as a force multiplier for Industry 4.0 in automotive, delivering measurable improvements in quality, cycle time, and customer loyalty.

For automotive OEMs, configurators reduce prototyping and production costs by preventing design mismatches, essential in an era of tight margins and high customization demands. They also accelerate lead times, enhancing responsiveness in supply chains.

By improving engagement, they support higher conversion rates and lower return volumes, both of which contribute to bottom-line performance.

Additionally, configurators feed into AI-driven systems: as data accumulates on customer choices, it can inform predictive analytics, production forecasting, and optimized manufacturing planning (especially relevant for SDVs)

Read Related: EVs and 3D Configurators: How Electric Car Brands Are Innovating

Conclusion

3D product configurators are no longer optional; they are essential tools at the crossroads of Industry 4.0, smart factory visualization, and digital transformation in manufacturing. By enabling interactive product customization, seamless B2B product configuration, and 3D product design automation, they deliver tangible value across production, sales, and customer experience.

Their role in supporting digital transformation in manufacturing will only become more critical as demand for mass customization, sustainability, and rapid innovation accelerates. Looking ahead, continued advances in visualization, AI, and automation promise even deeper integration with smart factories and digital twins. Embracing configurators is not just about keeping pace; it’s about leading the automotive industry into a future defined by innovation and resilience.

Are you using automation in your industry or struggling to connect digital workflows, design, and manufacturing for Industry 4.0?

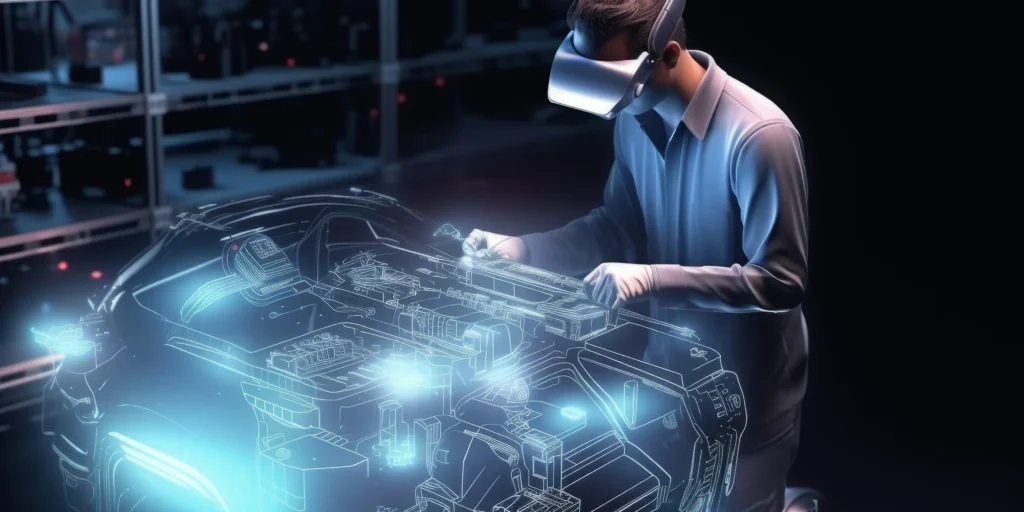

ProtoTech Solutions transforms factories into “smart” environments by delivering advanced custom vehicle configurators, CAD automation, and immersive 3D visualization platforms. We develop tools to streamline product design, accelerate customization, and integrate seamlessly with ERP and production systems. From interactive web-based configurators for automotive and manufacturing to custom CAD/BIM automation and AR/VR integrations, we empower manufacturers to boost productivity, reduce lead times, and enhance customer engagement.

With over 250 projects delivered globally, our expert engineering team helps you modernize your processes, automate complex tasks, and lead in the digital era of Industry 4.0. For more details, please connect with our experts today and see how we can help your business with AI-powered solutions.

Work Sample