The Importance of HVAC Duct Shop Drawings in Green Building Projects

According to Grand View Research, the global green building materials market was estimated to be valued at USD 285.89 billion in 2024 and is projected to reach USD 458.61 billion by 2030. This represents a compound annual growth rate (CAGR) of 8.5% from 2025 to 2030. The growth of this market is fueled by increasing awareness of climate change, government regulations promoting sustainable construction practices, and a rising demand for energy-efficient buildings.

HVAC Duct shop drawings are fundamental to the success of green building projects because they enable precision, collaboration, and long-term energy savings within sustainable construction. Architects, MEP contractors, and project managers are under increasing pressure to deliver buildings that meet energy efficiency goals and ensure compliance with standards such as LEED certification. Here’s a detailed look at why quality HVAC duct shop drawings are indispensable in sustainable construction.

What Are Duct Shop Drawings in HVAC?

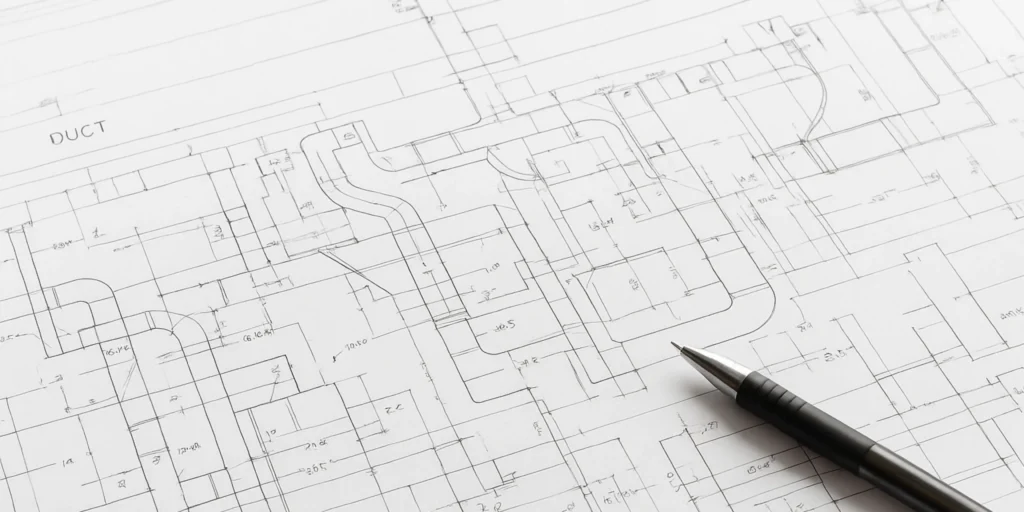

Duct shop drawings are highly detailed documents that show the exact layouts, dimensions, and specifications for HVAC duct systems within a building. Unlike generalized design drawings, shop drawings provide the level of detail needed for actual fabrication and installation, including individual duct sizes, precise routing, insulation specifications, and all interface points with other building services. These blueprints act as the “roadmap” for onsite crews, coordinating how every segment fits into complex environments and ensuring each component supports the HVAC system’s overall performance.

Consider a mid-rise office building aiming for LEED Gold. Early-stage coordination revealed numerous potential conflicts between duct runs, electrical trays, and fire-rated structural elements. Using precise HVAC duct shop drawings generated through BIM, the design team eliminated all clashes before fabrication. The result was a 15% reduction in onsite rework, 12% lower installation waste, and HVAC systems that operated at 95% of modeled energy efficiency, exceeding LEED thresholds for energy performance.

Why They Matter in Green Building Projects

Green buildings are designed with one overarching goal: reducing environmental impact while enhancing occupant comfort. Here’s how duct shop drawings directly support this mission:

1. Accurate Airflow and Load Calculations

When ductwork is designed precisely, HVAC systems don’t have to overcompensate for leaks, pressure drops, or inefficient routing. The result? Better energy efficiency in HVAC systems which lowers both operating costs and carbon emissions.

2. Reduced Material Waste

Improper or incomplete drawings often lead to excessive duct fabrication, offcuts, or rework. Shop drawings, however, provide exact measurements, helping contractors order the right amount of materials. This aligns perfectly with sustainable construction practices by reducing waste and lowering the project’s embodied carbon footprint.

3. Preventing Rework and Delays

Rework consumes time, labor, and resources, none of which are abundant on modern construction projects. Accurate duct shop drawings eliminate the need for last-minute changes, keeping projects on schedule and aligned with sustainability goals.

4. Compliance with Green Building Standards

Green certifications like LEED emphasize efficient HVAC performance and responsible resource use. Duct shop drawings help teams demonstrate compliance by documenting that ductwork layouts meet airflow, insulation, and energy-efficiency requirements.

Duct Shop Drawings and MEP Coordination

Green building projects demand close collaboration between trades. Ductwork must weave seamlessly through complex networks of plumbing, electrical, and structural systems. Without coordination, conflicts are inevitable, and conflicts lead to costly redesigns or on-site improvisation.

Clash-Free Installations

Shop drawings ensure that ductwork routing avoids clashes with pipes, conduits, and structural beams. This proactive approach saves material and energy while maintaining the building’s design integrity.

Role in BIM and Sustainable Design Workflows

Today, many duct shop drawings are integrated into Building Information Modeling (BIM) platforms. This digital workflow allows teams to simulate duct layouts, check for conflicts, and validate airflow performance before installation begins. By combining ductwork design with BIM, project teams enhance collaboration and strengthen the project’s sustainable construction outcomes.

Benefits for Energy-Efficient HVAC Systems

The HVAC system is one of the largest energy consumers in any building. Optimizing ductwork through high-quality shop drawings can deliver significant long-term savings and environmental benefits.

Optimized Routing Reduces Energy Losses

Every unnecessary bend or poorly sized duct increases friction and energy consumption. By carefully designing duct layouts, shop drawings ensure that air travels smoothly and efficiently through the system.

Supports Use of Eco-Friendly Materials

In sustainable projects, teams may specify ducts made from recycled metal or lined with environmentally friendly insulation. Shop drawings clarify where and how these materials should be applied, reducing the risk of improper installation.

Enhanced Indoor Air Quality

Green buildings focus not only on efficiency but also on occupant well-being. Accurate duct design ensures proper airflow distribution, contributing to healthier indoor environments.

Conclusion

In the push toward sustainable construction, small details often make the biggest difference. HVAC duct shop drawings may not be glamorous, but they are vital for delivering energy-efficient systems, reducing material waste, and ensuring seamless MEP coordination. They also play a direct role in meeting LEED certification requirements and other green building standards.

To maximize these benefits, many teams now partner with specialist outsourcing firms that bring expertise, advanced tools, and proven workflows to the shop drawing process. For stakeholders in the green building space, investing in comprehensive, accurate shop drawings is one of the smartest decisions for ensuring success. Prioritizing quality drawings on every project unlocks better building performance, smoother workflows, and a lasting legacy of energy efficiency.

If you want to redefine your approach to green building projects, talk to our experts at ProtoTech Solutions. With 20+ years of experience, our multidisciplinary team leverages advanced BIM modeling and CAD drafting tools like Revit and Navisworks to deliver highly detailed, clash-free duct shop drawings that streamline MEP coordination while supporting LEED and other green certification targets.