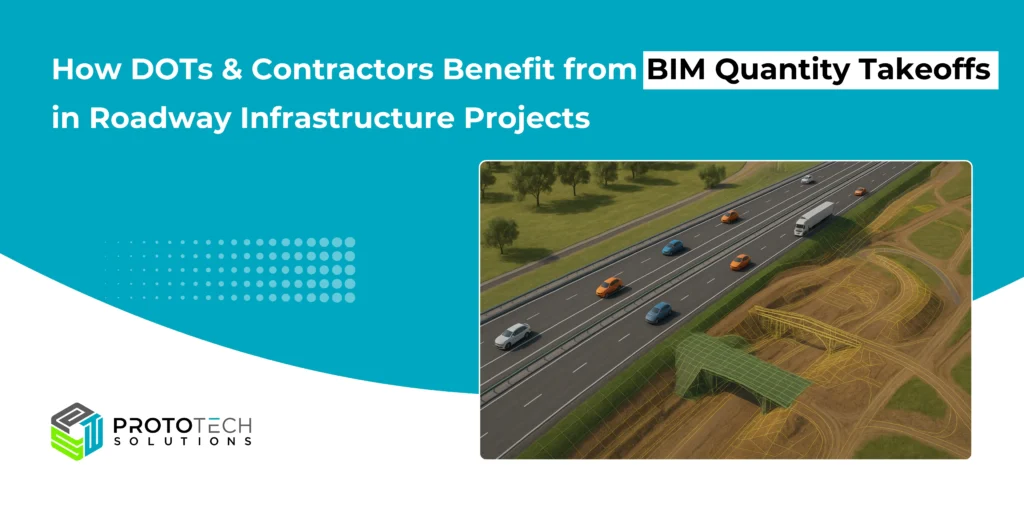

How DOTs and Contractors Benefit from BIM QTO in Roadway Infrastructure Projects

Roadway infrastructure projects demand significant investment in both cost and resources, making precision in cost estimation and material take-offs absolutely essential. Departments of Transportation (DOTs) and contractors are under constant pressure to complete projects on time, within budget, and with exceptional accuracy. This is precisely where BIM for Quantity Take-Off (QTO) and cost estimation revolutionizes the process, driving unparalleled efficiency, minimizing risks, and ensuring strict budget adherence. By embracing digital workflows, roadway stakeholders are decisively shifting away from outdated manual methods to adopt intelligent, automated, and exact cost estimation strategies.

In this blog, we’ll explore how DOTs and contractors benefit from BIM-based QTO in roadway projects, how it compares to manual methods, and why its adoption is transforming infrastructure construction.

The Importance of Accurate QTO in Roadway Projects

Cost overruns and delays are common in roadway construction projects, often resulting from inaccurate quantity take-offs, inadequate scope definition, or rework due to design conflicts. For DOTs, this can mean budget overruns, public scrutiny, and prolonged project delivery. Contractors face similar challenges, including loss of profit margins and reduced competitiveness during bidding.

By using digital quantity take-off for roads through BIM models, stakeholders gain a single source of truth for materials, dimensions, and construction sequencing, reducing errors and improving cost allocation.

What is BIM-Based Quantity Take-Off?

BIM-based Quantity Take-Off (QTO) leverages 3D intelligent models to extract precise quantities of roadway materials such as asphalt, concrete, culverts, retaining walls, and guardrails. Since the data comes directly from the model, the take-off process is automated, consistent, and repeatable.

Unlike 2D plans, BIM provides not only geometry but also metadata, extending to material specifications, cost rates, phasing, and performance attributes. This makes BIM-driven cost estimation more dynamic, enabling teams to test multiple design and phasing alternatives while maintaining budget visibility.

The integration of cost estimation within BIM provides real-time visibility into project budgets, allowing DOTs and contractors to make data-driven decisions early in the project lifecycle.

BIM vs Manual Take-Off in Roadway Projects

| Criteria | BIM for Quantity Take-Off | Manual Quantity Take-Off |

| Accuracy | Ensures high accuracy with model-based data | Prone to errors and omissions due to manual calculations |

| Time Efficiency | Automated QTO extraction reduces effort and speeds estimates | Labor-intensive, requiring repetitive calculations |

| Design Changes | Updates instantly when the model changes | Requires rework for every design revision |

| Roadway Construction Cost Accuracy with BIM | Improves forecasting with real-time updates | Increased risk of cost overruns |

| Collaboration | Enhances coordination among DOTs, designers, and contractors | Limited collaboration, data often siloed |

| Competitiveness in Bidding | Enables precise bids with lower risk | Less confidence in estimates leads to conservative bids |

| Project Transparency | Provides audit trails of QTO data for accountability | Difficult to validate quantities manually |

For DOTs and contractors, the infrastructure project cost control with BIM is not just a technical advantage but a financial safeguard.

Benefits for DOTs in Roadway Projects

DOTs are under pressure to deliver large-scale highway projects efficiently, with reduced waste and greater accountability. BIM adoption by DOTs offers the following advantages:

- Budget optimization by leveraging accurate QTO forecasts.

- Reduced disputes through transparent data sharing with contractors.

- Standardization across state and federal projects for consistency.

- Public accountability with documented digital records.

- Sustainability gains are achieved by minimizing surplus materials and optimizing resource use.

By standardizing digital quantity take-off for roads, DOTs not only reduce waste but also improve long-term maintenance planning.

Benefits for Contractors in Roadway Projects

For contractors, accurate QTO can make or break project profitability:

- Enhanced bidding confidence through precise material estimation.

- Cost savings by avoiding waste and over-purchasing.

- Reduced change orders from unexpected scope revisions.

- Competitive advantage through faster proposal turnaround.

- Integration with project scheduling for time-phased budgets.

Ultimately, the benefits of BIM for contractors in road projects extend beyond cost control—they directly enhance reputation, competitiveness, and project delivery capability.

Roadway Project Cost Savings Using BIM

Research shows that highway construction QTO automation can reduce cost overruns by up to 15–20%. For large-scale projects spanning millions of dollars, this translates into significant savings. When DOTs and contractors align on BIM-driven cost estimation, the result is lower risk, smoother approvals, and better stakeholder buy-in.

Imagine a large highway expansion project where design changes are frequent. In a manual process, each revision could take days or weeks to recalculate material quantities and adjust the budget. With BIM, updates are immediate, quantities, costs, and schedules adjust dynamically. This level of agility provides both DOTs and contractors with confidence in their cost control strategies.

The Impact of BIM on the Future of Cost Estimation

BIM has fundamentally transformed the future of cost estimation in construction by boosting accuracy, automating processes, enabling real-time updates, and driving collaboration among stakeholders. The ongoing evolution of BIM promises even greater integration with AI, sustainability analysis, and cloud-based platforms.

- Enhanced Accuracy: BIM enables precise quantity takeoffs from 3D models, reducing manual errors and improving workflows. Automated extraction leads to reliable cost breakdowns, minimizing overruns and rework.

- Real-Time Cost Updates: Design changes are instantly reflected in cost estimates, allowing teams to adapt to variations and budget constraints while maintaining aligned financial planning.

- Collaborative: Detailed digital models facilitate better collaboration among architects, engineers, and contractors, fostering early issue detection and optimizing project designs for more accurate budgeting.

- Advanced Technologies: The future of BIM-based cost estimation includes AI and machine learning for improved forecasts, alongside emerging technologies like AR/VR and cloud platforms to enhance efficiency and stakeholder engagement.

Read Related: BIM Modeling: Transforming Digital Construction for Efficiency and Sustainability

FAQs on BIM Quantity Take-Off in Roadway Projects

Q. How does BIM reduce errors in roadway cost estimation?

BIM eliminates manual counting errors by automating material quantification directly from 3D models. This leads to higher accuracy and fewer cost overruns in roadway projects.

Q. Why do DOTs prefer BIM for infrastructure projects?

DOTs prefer BIM because it standardizes workflows, improves accountability, and reduces disputes with contractors by providing transparent cost and QTO data.

Q. What is the role of the BIM-driven bidding process for contractors?

BIM-driven bidding helps contractors generate precise estimates quickly, increasing their competitiveness while reducing the risk of underbidding or overpricing in highway projects.

Q. How does automated QTO improve highway construction projects?

Automated QTO streamlines material quantity calculations, speeds up estimation, and reduces rework, making highway construction projects more efficient and cost-effective.

Q. What is the role of BIM in roadway project budgeting?

BIM provides accurate, real-time insights into material, labor, and equipment needs, helping contractors and DOTs plan budgets effectively and avoid unexpected overruns.

Conclusion

Both DOTs and contractors benefit immensely from adopting BIM for roadway QTO. The move from manual to model-based workflows ensures cost accuracy, stronger collaboration, and improved transparency in infrastructure delivery.

Successfully implementing BIM quantity takeoffs requires skilled professionals who can effectively use BIM software to extract accurate quantities from the model. To ensure the successful adoption of BIM quantity takeoffs in cost estimation services, training and upskilling the workforce are essential.

At ProtoTech Solutions, our BIM modeling services help engineers, contractors, and DOTs implement digital cost control solutions that reduce risk, improve project ROI, and ensure on-time delivery of roadway infrastructure projects. Whether it’s QTO automation, 5D BIM integration, or project-specific cost simulations, we bring the tools and expertise to make your next highway project smarter, leaner, and more cost-efficient.

Ready to modernize your roadway infrastructure projects? Contact ProtoTech today to learn how our BIM Modeling expertise can transform your workflows.