How Digital Twins Can Help in Predicting Equipment Failures

The digital twin market is growing fast because of advances in IoT, AI, cloud computing, and Industry 4.0. Industries like manufacturing, healthcare, smart cities, and automotive are adopting this technology quickly.

Research shows the digital twin market is set to jump from $24.97 billion in 2024 to $155.84 billion by 2030. That’s a 34.2% yearly growth. This technology connects the physical world and its virtual copy, helping improve product design, predict when machines might fail, and boost efficiency.

One big problem companies face is predicting machine breakdowns. Unexpected failures cause costly downtime and safety issues. Digital twins help spot problems early and keep things running smoothly.

This blog explains how digital twins predict equipment failure, why they matter for business, and how you can use them to save money and work better.

What is a Digital Twin?

A digital twin is a virtual representation of a real machine or system. It mirrors what the real asset is doing at any moment. These models use sensor data, internet-linked devices, and simulations to reflect real-time actions. Think of it like a flight simulator for machines and processes.

For example, imagine a digital twin of a wind turbine. This twin receives real-time data from the actual turbine temperature, vibration, wind speed, and energy output, and uses this information to model how the turbine is functioning. If anything starts to go off track, the digital twin can spot it quickly and even forecast future problems.

Components of a Digital Twin

- Sensors and Data Collection: IoT sensors collect continuous data such as temperature, pressure, and vibrations.This data streams into the digital twin, updating its virtual model in real time.

- Data Analysis and AI: Advanced algorithms analyze data, find patterns, and predict issues. It detects subtle changes and patterns that might signal early signs of wear, degradation, or malfunction, often before any visible symptoms appear

- Modeling and Simulation Tools: The twin lets you test maintenance plans safely in a virtual space. You can try different approaches without risking real equipment.

- Predictive Analytics & Failure Forecasting: By using past trends and live data, digital twins predict when and how machines might fail. Maintenance teams get alerts and advice to act at the right time.

Digital twins stay synced with their real machines through constant data flow. Testing “what if” scenarios shows how a machine could behave. This lets workers catch faults early, saving time and money.

Why Use Digital Twins for Equipment Failure Prediction?

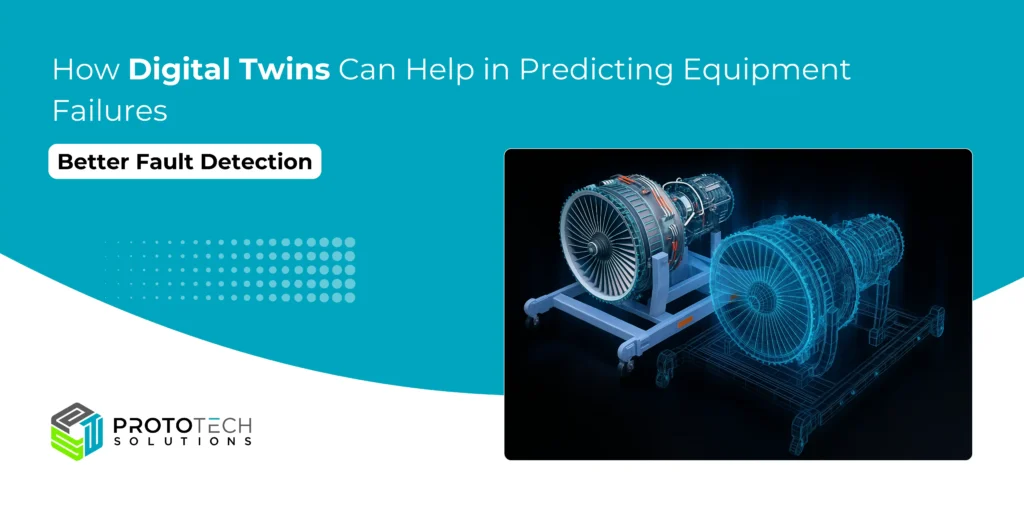

- Better Fault Detection

Digital twins catch tiny warning signs that humans or simple systems might miss. Continuous data helps spot subtle changes in machine health. This cuts down false alarms and missed problems, making maintenance more reliable.

- Smarter Maintenance Plans

Instead of fixing machines after they break, you fix them when signs appear. This switch helps machines last longer and lowers sudden breakdowns.

- Saving Money and Improving Operations

Downtime costs lots of money. Digital twins prevent unexpected stops by catching problems early. Companies like General Electric use this tech for jet engines, saving millions and keeping flights safe.

How To Start Using Digital Twins in Equipment Failure Prediction

- Gather and Combine Data

Good sensors are essential. They collect the information your digital twin needs to mirror the real machine. Mixing data from different sources helps you get a clear view of the equipment’s condition.

- Developing a Good Digital Twin Model

Use past data along with live updates to create a digital twin you can count on. Blend physics-based models with data analysis for a more accurate virtual copy.

- Overcoming Challenges

Protect your data from theft and privacy issues. Test your models carefully before using them fully. Machines with many parts might need separate models, but careful planning can keep them simple.

Real-World Examples and Success Stories

Digital twins can save money, improve safety, and make maintenance easier. Start small, test thoroughly, and learn as you go.

- Manufacturing Success

Siemens has built digital twin platforms that track equipment and predict failures well before they happen. This leads to less downtime and faster repairs.

- Power Plants

Power stations now use digital twins for turbines. They quickly detect issues so repairs can be scheduled during planned shutdowns, not during work.

- Aviation

Airlines use digital twins to monitor engines. This tech catches problems early, saving cash and avoiding delays or accidents.

Final Thoughts

Digital twins can change how industries avoid equipment failures. They give clearer insights, lower costs, and improve safety. Companies that use this tech will stay ahead in today’s world. Digital twins lead to smarter, safer, and more efficient operations. Start today, the future is ready.

If you want to protect your operations, now is the time to try digital twins. The tech is ready, the benefits are real, and the edge is yours to gain. Let’s Talk