Top 5 Benefits of Isometric Drawing Applications in Cryogenic Piping Systems

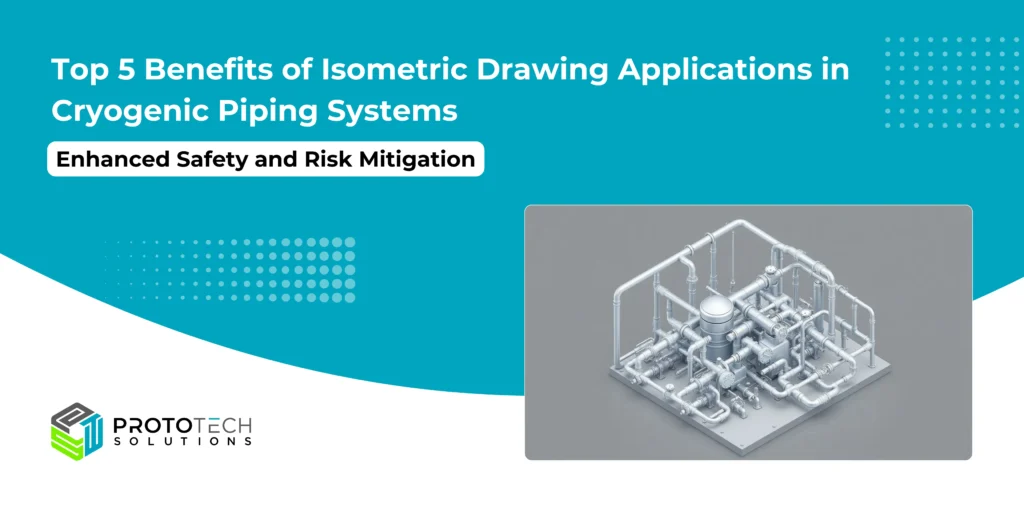

Cryogenic piping systems, designed to transport extremely low-temperature fluids like liquid nitrogen or liquefied natural gas (LNG), are a cornerstone of industries such as aerospace, healthcare, and energy. The design and maintenance of these systems require precision, as any error can result in inefficiencies or, worse, safety hazards. One essential tool in managing these challenges is the use of isometric drawing applications. These advanced tools transform the way cryogenic piping systems are visualized, constructed, and maintained.

What is Meant by Isometric Drawing?

Isometric Drawing is a type of technical drawing that represents a three-dimensional object in two dimensions. It is commonly used in engineering, architecture, and design to provide a clear visual representation of an object or structure. In an isometric drawing, the three principal axes of the object (height, width, and depth) are represented equally foreshortened and inclined at equal angles, typically 120° apart from each other. By using isometric drawing, designers can communicate complex ideas visually and ensure precision in construction or manufacturing processes.

Key Features of Isometric Drawing:

- Equal Scaling: All axes are scaled equally to maintain proportionality, which makes measuring and interpreting dimensions straightforward.

- Angle of Projection: The drawing is based on isometric projection, where the axes are inclined at 30° to the horizontal plane, resulting in a uniform, three-dimensional appearance.

- No Perspective: Unlike perspective drawing, isometric drawings do not include vanishing points, so parallel lines remain parallel.

- Clarity: Objects are drawn with all visible edges and surfaces shown without distortion, making them easy to understand for technical purposes.

Let’s dive into the benefits of using isometric drawing applications in cryogenic piping systems.

Benefits of Isometric Drawing Applications in Cryogenic Piping Systems

Visualizing the cold is essential in the design and maintenance of cryogenic piping systems. Isometric drawings play a crucial role in achieving success in these complex projects.

1. Enhanced Visualization and Clarity

Isometric drawings provide a three-dimensional representation on a two-dimensional plane, making it easier to visualize the piping layout. Unlike traditional orthogonal drawings, isometric projections offer a holistic view of the piping network, showing length, width, and height in a single image.

For cryogenic piping systems, which often have complex layouts with multiple layers of insulation and intricate routing, this clarity is indispensable. Engineers can better understand spatial relationships, identify potential clashes, and ensure that every component fits seamlessly within the design constraints. Visual accuracy helps both designers and contractors minimize misinterpretations, reducing the risk of costly errors during construction.

2. Improved Design Accuracy

Precision is non-negotiable in cryogenic systems due to the extreme temperatures and pressures involved. Isometric drawing applications integrate with Computer-Aided Design (CAD) tools, enabling engineers to create accurate models that include detailed specifications such as pipe diameter, material, insulation thickness, and support structures.

These tools allow for easy implementation of industry standards and codes, ensuring compliance with safety and performance regulations. With built-in error-checking features, isometric drawing applications can automatically detect inconsistencies or clashes in the design, helping teams address issues before they escalate.

3. Streamlined Fabrication and Assembly

Fabricating and assembling cryogenic piping systems require meticulous planning. Isometric drawings play a pivotal role in translating design into reality by providing detailed spool drawings and fabrication instructions. These include:

- Exact dimensions of pipes and fittings.

- Clear labeling of components.

- Weld locations and cut lengths.

This level of detail ensures that workshop technicians and site workers have a clear blueprint to follow, minimizing ambiguities. Additionally, these drawings help streamline the procurement process by specifying exact material requirements, reducing waste and ensuring timely availability of components.

4. Enhanced Maintenance and Troubleshooting

Maintenance is a critical aspect of cryogenic piping systems, as even minor faults can disrupt operations or pose safety risks. Isometric drawing applications simplify maintenance by providing accurate and easy-to-read diagrams of the system’s layout. Technicians can quickly locate valves, joints, and other components, saving time during inspections and repairs.

In addition, these drawings serve as a reference for troubleshooting. With the help of isometric applications, engineers can simulate scenarios, analyze potential failure points, and implement solutions without disrupting the actual system. This predictive capability is especially valuable in preventing downtime and extending the system’s operational lifespan.

5. Conflict Resolution and Compliance Assurance

In complex projects involving multiple stakeholders, conflicts can arise due to overlapping designs or miscommunication about specifications. Isometric drawings help identify potential spatial clashes before construction begins, allowing teams to address these issues proactively rather than reactively. This foresight is critical in cryogenic piping systems where safety standards are stringent due to the risks associated with handling super-cooled substances. Additionally, by adhering to established drawing standards, isometric applications ensure compliance with industry regulations and safety protocols.

Revolutionizing Cryogenic Piping Systems with ProtoTech Solutions

Isometric drawing applications are transforming the cryogenic piping industry by offering unmatched clarity, precision, and efficiency. These tools help streamline design, enhance collaboration, and reduce errors, making them indispensable for complex engineering projects.

At ProtoTech Solutions, we are developing cutting-edge engineering software tailored to our client’s unique needs. With over 20 years of expertise in CAD customization, 3D visualization, AR/VR, and BIM modeling, our development team has successfully crafted isometric drawing applications that empower clients worldwide to optimize their workflows.

Let us help you unlock the full potential of isometric drawing applications in your cryogenic piping projects. Reach out today to learn how ProtoTech Solutions can be your trusted partner in innovation.