How 3D Product Configurators Help Elevator Manufacturers Design Lift and Build Process

According to recent market research, the global elevator market was valued at USD 79.06 billion in 2024 and is expected to reach USD 116.14 billion by 2030, growing at a CAGR of 6.7% between 2025 and 2030. This strong growth is fueled by rapid urbanization, increased infrastructure development, and continuous technological innovation.

As cities grow taller and populations increase, the demand for smart, safe, and efficient vertical transportation systems such as elevators continues to rise. From residential buildings to commercial and industrial facilities, elevators are now a critical part of modern infrastructure.

In today’s fast-paced manufacturing environment, elevator manufacturers face mounting pressure to deliver customized solutions quickly and efficiently. With rising customer expectations and complex architectural needs, traditional design methods often fall short. This is where 3D product configurators come into play.

A mid-sized elevator company implemented a 3D configurator to allow architects and builders to design elevators based on building plans. The configurator reduced the average project design time from 4 weeks to just 2 days. It also led to a 30% increase in the quote-to-order conversion rate.

In this post, we’ll explore how 3D product configurators help elevator companies enhance their design and production workflows.

What Is a 3D Product Configurator?

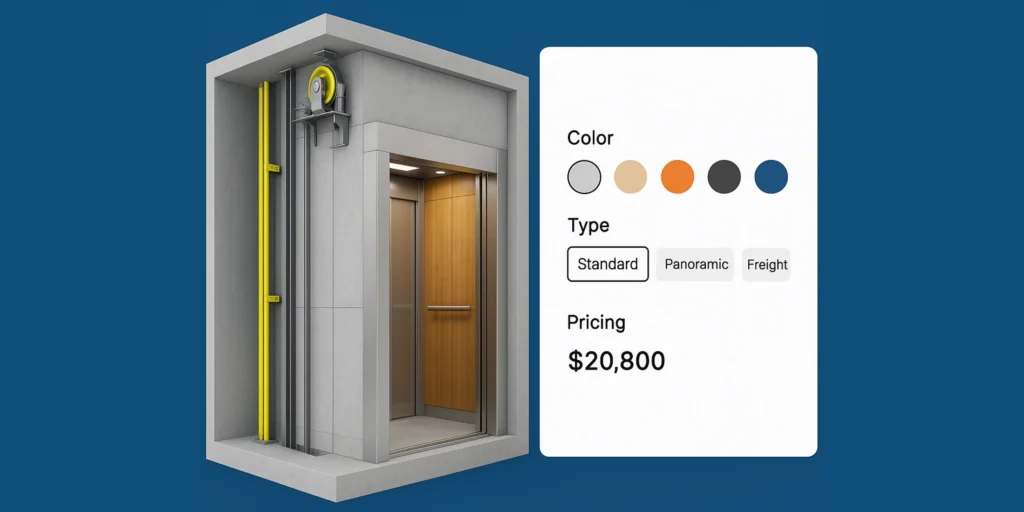

A 3D product configurator is an interactive software application that allows users to visualize and customize products in real-time. For elevator manufacturers, this means creating detailed, accurate 3D models of lifts, adjusting dimensions, materials, and features on the fly, and instantly seeing the results. The configurator bridges the gap between design, engineering, sales, and production, ensuring everyone is on the same page from concept to completion.

Once the configuration is complete, the software often generates real-time pricing, technical drawings, and production-ready files automatically.

Top 6 Key Considerations for an Elevator Designer

Here are some of the ways 3D product configurators can be applied to elevator manufacturing:

1. Passenger Traffic

Understanding the building’s function and daily passenger flow is essential. Different building types, residential, commercial, industrial, or healthcare, have unique elevator needs. For example, office buildings experience peak traffic during mornings and evenings, hospitals require space for stretchers, and industrial lifts must handle heavy loads and materials safely. Analyzing peak usage times helps determine the number, size, and type of elevators needed to avoid congestion and long wait times.

2. Design Style and Customization

Elevators should complement the building’s architectural style and tenant expectations. Designers must consider interior finishes, materials, lighting, and branding elements to create an appealing and functional cabin that fits the overall aesthetic

3. Safety and Compliance

Safety is paramount in elevator design. Elevators must meet all relevant codes and standards, including emergency braking systems, fire-resistant materials, overload sensors, intercoms for emergencies, and backup power. Accessibility features such as braille buttons and voice announcements ensure inclusivity for all users.

4. Lift Size and Capacity

The elevator size should accommodate the expected number of passengers or goods. Residential lifts may be smaller, while commercial or hospital elevators require larger cabins. In industrial settings, cabin dimensions must fit pallets or forklifts if materials are transported.

5. Drive System and Speed

Choosing the right drive system (hydraulic, traction, gearless) affects elevator speed, efficiency, and cost. Taller buildings often need faster, gearless traction elevators to minimize wait times. Technology like traffic management software can optimize elevator movement and reduce energy consumption

6. Energy Efficiency

Incorporating energy-saving technologies such as regenerative drives, LED lighting, and efficient motors reduces operating costs and supports sustainability goals

How 3D Configurators Help Elevator Manufacturers

1. Custom Elevator Shaft Design

Elevators are rarely “one-size-fits-all.” Architects and building owners often require unique dimensions, finishes, and functionalities. With a 3D configurator, manufacturers can:

- Quickly adjust shaft size, cabin dimensions, and door types to fit specific building requirements.

- Instantly visualize customizations, reducing the time spent on back-and-forth communications.

- Generate accurate 3D renderings and technical drawings for client approval and engineering.

2. Cabin Interior Customization

Customers can use the configurator to choose from different cabin finishes, panel styles, lighting options, and handrails, helping them visualize how their elevator will look in real-time. This creates a more engaging sales experience and improves customer satisfaction.

3. Component Selection and Load Calculations

The configurator can include logic-based rules to ensure users only select compatible components such as motors, control systems, or safety devices, based on desired speed, travel distance, and weight capacity. This ensures regulatory compliance and engineering accuracy.

4. Streamlined Workflow from Design to Production

Integrating 3D configurators with CAD and manufacturing systems enables a seamless transition from digital design to physical production:

- Design changes made in the configurator are instantly reflected in engineering models and manufacturing documentation.

- Automated workflows eliminate repetitive manual tasks, accelerating the time from order to installation.

- Production teams receive clear, validated instructions, improving efficiency and reducing lead times.

5. Real-Time Quoting and BOM Generation

Once the design is finalized, the software can instantly generate a bill of materials (BOM), estimated production timeline, and cost quote. This reduces delays and helps align the sales, engineering, and production teams.

Read Relevant: How CPQ Product Configurators Help Furniture Manufacturers

Conclusion

If you work in manufacturing today, you likely face pressure to offer more options, deliver faster, and reduce mistakes, all while controlling costs. The good news is that a product configurator can help. This software automates customization and streamlines quoting and production, changing how manufacturers design, sell, and grow their business.

In the blog post above, we explain what a product configurator is, how it works, and why using one can transform your operations.

Want to build your elevator configurator? Connect with ProtoTech Solutions, we have developed many configurator tools for our clients worldwide, achieving a 95% satisfaction rate.

Let’s talk about what’s possible and start building a smarter, faster future for your manufacturing business.